Différences entre versions de « Rasp-PiGRRL-2-3D »

(Page créée avec « {{Rasp-PiGRRL-2-NAV}} {{traduction}} {{Rasp-PiGRRL-2-TRAILER}} ») |

|||

| Ligne 2 : | Ligne 2 : | ||

{{traduction}} | {{traduction}} | ||

| + | == Introduction == | ||

| + | {{ADFImage|Rasp-PiGRRL-2-3D-01.jpg|640px}} | ||

| + | |||

| + | == Material Options == | ||

| + | The top case, bottom case and shoulder mount should be printed in hard plastic like PLA, ABS or other. We recommend using PLA to minimize warping. ABS and other filaments requires a heated bed. | ||

| + | |||

| + | {{ADFImage|Rasp-PiGRRL-2-3D-02.jpg|640px}} | ||

| + | |||

| + | == Parts == | ||

| + | Download the parts and print them out accordingly - referencing the table below for material suggestions. If you don't have access to a 3D printer, use a service like <a href="http://3dhubs.com">3DHubs.com</a> to send them to you. | ||

| + | |||

| + | == Dimensions == | ||

| + | |||

| + | * Top Part – 141mm x 91mm x 18mm (5.55in x 3.85in x 0.71in) | ||

| + | * Bottom Part – 141mm x 91mm 16mm (5.55in x 3.85in x 0.63in) | ||

| + | |||

| + | {{asm-begin}} | ||

| + | {{asm-row|img=Rasp-PiGRRL-2-3D-03.jpg}} | ||

| + | {{asm-img|img=Rasp-PiGRRL-2-3D-04.jpg}} | ||

| + | {{asm-img|img=Rasp-PiGRRL-2-3D-05.jpg}} | ||

| + | {{asm-img|img=Rasp-PiGRRL-2-3D-06.jpg}} | ||

| + | {{asm-img|img=Rasp-PiGRRL-2-3D-07.jpg}} | ||

| + | {{asm-text}} | ||

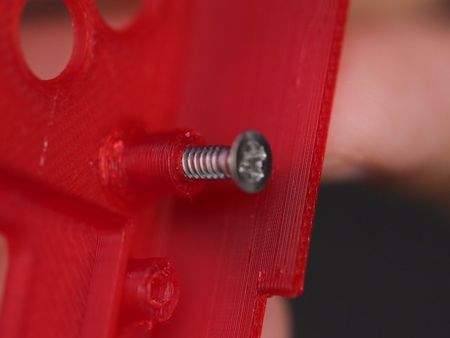

| + | After the parts are finished printing, you'll need to tap the standoffs with screw holes to create the threads for mounting the components. Use a #4-40 and #2-56 sized tap or use machine screws. | ||

| + | |||

| + | {{asm-row|img=Rasp-PiGRRL-2-3D-08.jpg}} | ||

| + | {{asm-text}}Be careful tapping the standoffs from the top -To prevent puncturing the surface, '''DO NOT''' tap all the way through the standoff. Be careful not to tap too fast or forcefully to avoid damaging the standoffs. | ||

| + | |||

| + | {{asm-end}} | ||

| + | == Test Fit Openings == | ||

| + | Use a hobby knife to remove any excess bits from printing. Lay the components over the standoffs to see if mounting holes line up. See if the port cutouts are in the right place. If they don't, use a filing tool to open them up. | ||

| + | |||

| + | == Finishing Parts == | ||

| + | You can smooth the parts by applying epoxy resin like Smooth-On's XTC-3D. To finish the surface, wait for it to dry and sand it down. Apply a filler primer paint and a colored top coat of spray paint to make it extra smooth. | ||

| + | |||

{{Rasp-PiGRRL-2-TRAILER}} | {{Rasp-PiGRRL-2-TRAILER}} | ||

Version du 5 février 2018 à 21:26

|

|

En cours de traduction/élaboration. |

Introduction

Crédit: AdaFruit Industries www.adafruit.com

Material Options

The top case, bottom case and shoulder mount should be printed in hard plastic like PLA, ABS or other. We recommend using PLA to minimize warping. ABS and other filaments requires a heated bed.

Crédit: AdaFruit Industries www.adafruit.com

Parts

Download the parts and print them out accordingly - referencing the table below for material suggestions. If you don't have access to a 3D printer, use a service like <a href="http://3dhubs.com">3DHubs.com</a> to send them to you.

Dimensions

- Top Part – 141mm x 91mm x 18mm (5.55in x 3.85in x 0.71in)

- Bottom Part – 141mm x 91mm 16mm (5.55in x 3.85in x 0.63in)

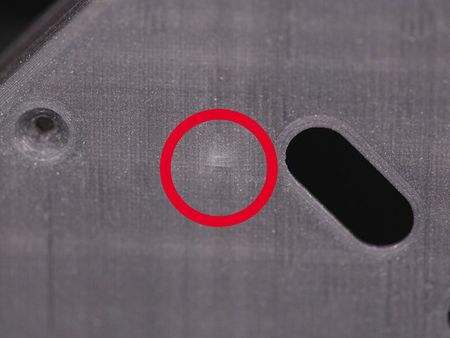

Test Fit Openings

Use a hobby knife to remove any excess bits from printing. Lay the components over the standoffs to see if mounting holes line up. See if the port cutouts are in the right place. If they don't, use a filing tool to open them up.

Finishing Parts

You can smooth the parts by applying epoxy resin like Smooth-On's XTC-3D. To finish the surface, wait for it to dry and sand it down. Apply a filler primer paint and a colored top coat of spray paint to make it extra smooth.

Source: PiGRRL 2 - Make a portable Raspberry Pi 2 game console

Créé par les frères Ruiz pour AdaFruit Industries.

Traduction réalisée par Wrotny A pour MCHobby.be.

Toute référence, mention ou extrait de cette traduction doit être explicitement accompagné du texte suivant : « Traduction par MCHobby (www.MCHobby.be) - Vente de kit et composants » avec un lien vers la source (donc cette page) et ce quelque soit le média utilisé.

L'utilisation commercial de la traduction (texte) et/ou réalisation, même partielle, pourrait être soumis à redevance. Dans tous les cas de figures, vous devez également obtenir l'accord du(des) détenteur initial des droits. Celui de MC Hobby s'arrêtant au travail de traduction proprement dit.

Traduit avec l'autorisation d'AdaFruit Industries - Translated with the permission from Adafruit Industries - www.adafruit.com