ENG-CANSAT-V2-ASSEMBLY

Révision datée du 29 juillet 2025 à 20:46 par Admin (discussion | contributions) (→Assembling the Cansat)

Abstract

The original version of the CANSAT kit required many soldering operation. It's intimidating for newcomers with little experience with a soldering iron.

With the CANSAT V2 kit, things have been made easier than ever, no solder required!

Assembling the Cansat

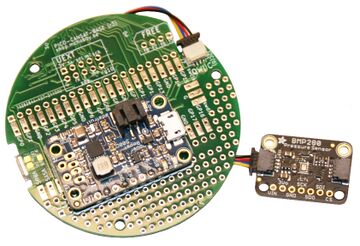

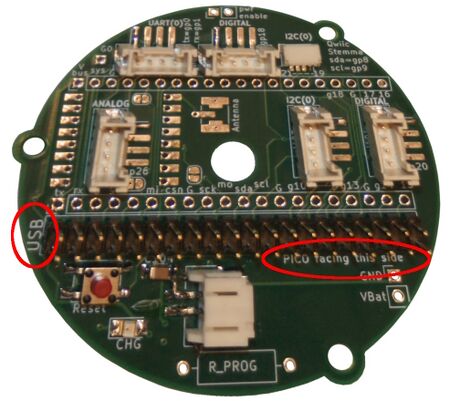

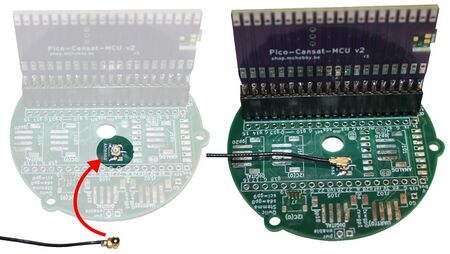

Let's prepare the main CANSAT board.

|

Take the base board and orient the board to see the USB label on the left and the "Pico/MCU facin this side" in front of you. | ||

|

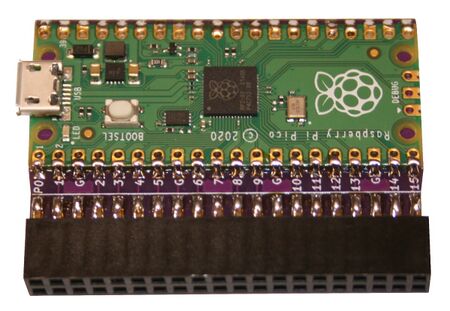

Grab the CPU board with the microcontroler facing front. | ||

|

Now, insert the MCU board onto the 2x20 pin connector. | ||

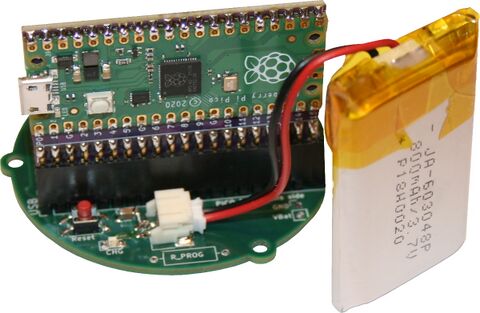

| 450px | Even when not required yet, user can pick the Lipo battery then plug it into the 2 poles JST connector (facing the microcontroler).

| ||

|

When required, plug the µFl antenna coax.

|

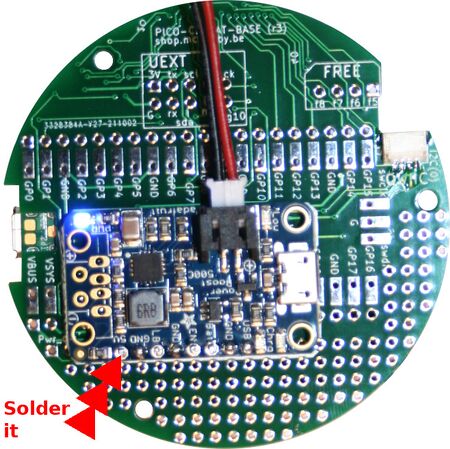

Lipo Booster soldering

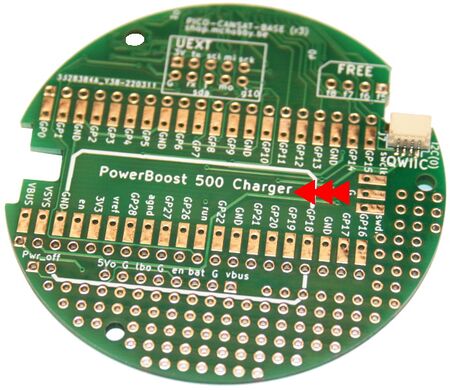

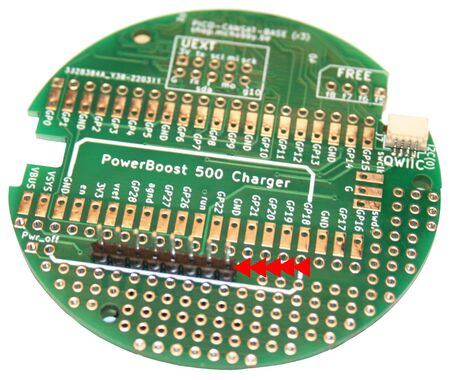

The kit can be used either with a PowerBoost 500 Charger, either a PowerBoost 1000 Charger.

The soldering operation depends on the selected PowerBoost model.

PowerBoost 500 Charger Soldering

The PowerBoost 500 is the default powering system of this kit.

| The instructions doesn't applies to the PowerBoost 1000 charger. |

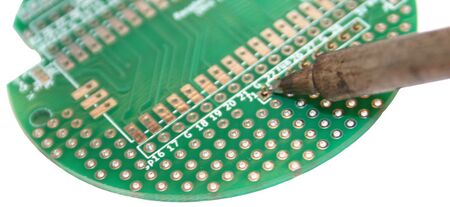

Let's solder it

Written by Meurisse D. for MCHobby