Différences entre versions de « Pololu-Zumo-Shield-Arduino-assembler-shield »

| Ligne 58 : | Ligne 58 : | ||

* Place an M3 nut in each of the two side slots near the rear of the chassis. The slots are sized so that nuts will not be able to rotate within them. (These nuts will be used to mount the idler sprockets later.) | * Place an M3 nut in each of the two side slots near the rear of the chassis. The slots are sized so that nuts will not be able to rotate within them. (These nuts will be used to mount the idler sprockets later.) | ||

* If you want, peel the protective paper masking off both sides of the acrylic spacer plate pieces (the spacer plates in our pictures show what they will look like with the masking peeled off). Alternatively, you can leave the masking on for additional thickness. If you leave the masking on, it will be mostly concealed when the robot is fully assembled. | * If you want, peel the protective paper masking off both sides of the acrylic spacer plate pieces (the spacer plates in our pictures show what they will look like with the masking peeled off). Alternatively, you can leave the masking on for additional thickness. If you leave the masking on, it will be mostly concealed when the robot is fully assembled. | ||

| − | * Cover the chassis and motors with the spacer plate pieces and then the Zumo shield. The holes in the spacer plate should line up with the through-holes in the shield resting on top of it, and the motor leads should be aligned so they pass through the slots in the spacer as shown in the picture below. There is only one correct orientation for these plates. (The plate consists of two separate pieces to make it possible to disassemble the Zumo without having to desolder the motors or battery terminals.) | + | * Cover the chassis and motors with the spacer plate pieces and then the Zumo shield. {{underline|The holes in the spacer plate should line up with the through-holes in the shield resting on top of it, and the motor leads should be aligned so they pass through the slots in the spacer as shown in the picture below}}. There is only one correct orientation for these plates. (The plate consists of two separate pieces to make it possible to disassemble the Zumo without having to desolder the motors or battery terminals.) |

| + | |||

| + | {{POLImage|Pololu-Zumo-Shield-Arduino-assembler-shield-40.jpg|350px|Entretoise en plexiglas positionné au dessus du châssis Zumo}} | ||

| + | |||

| + | * In each of the four mounting holes, insert a #2-56 machine screw through the shield, spacer plate, and chassis, and tighten it against a nut under the chassis. It is usually easier to place the nut into the recess first and hold it there with a finger or piece of tape while inserting the screw. Note that the kit includes two different sizes of #2-56 machine screws: 1/4″and 5/16″. The two longer screws are intended for use in the front holes (near the motors) if you are also mounting a sumo blade; otherwise, you can use the shorter 1/4″ screws for all four mounting holes. | ||

| + | |||

| + | If you are also adding a basic sumo blade, you can either mount it now or add it later after you are done soldering the motors and battery contacts. ('''Note:''' If you intend to solder anything to the front expansion area of the shield, such as a Zumo reflectance sensor array, you will have more room to work if you do the soldering before adding the sumo blade.) | ||

| + | |||

| + | {{ambox|text=There is a small chance the mounting tabs of the blade can cause shorts where it contacts the shield if the PCB solder mask is not thick enough, so we recommend adding some electrical tape or other insulating material between the blade and shield.}} | ||

| + | |||

| + | To install the blade, first bend its mounting tabs to the appropriate angle. Next, place them on top of the shield so that the holes line up with the two front mounting holes and insert the two longer (5/16″) #2-56 machine screws (included with the shield) through the blade, shield, spacer plate, and chassis. Be careful when adjusting the angle of the sumo blade while it is mounted to the chassis, as this can crack the acrylic spacer plate if you apply sudden or excessive force. We recommend you do not try bending the blade while it is mounted to the chassis. | ||

| + | |||

| + | {{POLImage|Pololu-Zumo-Shield-Arduino-assembler-shield-42.jpg|350px|Shield placé au dessus du châssis Zumo}} | ||

| + | |||

| + | * Solder each motor lead to the shield, then trim off the excess length of wire. | ||

| + | |||

| + | {{POLImage|Pololu-Zumo-Shield-Arduino-assembler-shield-41.jpg|350px|Moteurs soudés sur le Zumo Shield}} | ||

| + | |||

| + | == Contacts des piles == | ||

| + | * Turn the chassis over and install the battery terminal contacts as shown in the picture below. The three double-contact pieces should be firmly pressed into place until they are flush with the interior surface of the battery compartment. The two individual contacts should be inserted into the battery compartment so that their solder tabs protrude through the holes in the top of the chassis; you might want to temporarily tape these two individual contacts in place until they have been soldered to the shield as described in the next step, or you can use a battery to temporarily hold them in place. | ||

| + | |||

| + | {{POLImage|Pololu-Zumo-Shield-Arduino-assembler-shield-50.jpg|350px|Ajouter les connecteurs des piles sur le châssis et les piles}} | ||

{{Pololu-Zumo-Shield-Arduino-TRAILER}} | {{Pololu-Zumo-Shield-Arduino-TRAILER}} | ||

Version du 7 avril 2017 à 15:18

|

|

En cours de traduction/élaboration. |

Introduction

Please follow these instructions carefully to assemble your Zumo Shield and chassis properly. (These pictures show the original Zumo Shield lien pololu , but the assembly process is the same for the latest v1.2 version lien pololu )

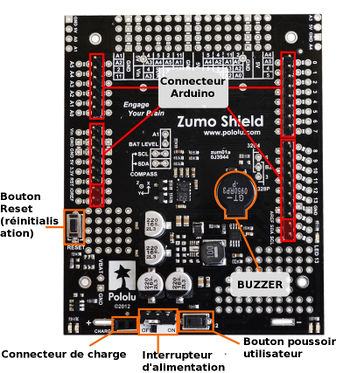

Les composants traversants

- Solder the included through-hole components to the shield:

- power switch

- reset pushbutton

- user pushbutton

- buzzer

- charging connector (1×2-pin female header)

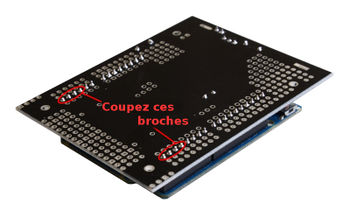

- On the bottom of the board, trim any leads longer than 1/16″ (the thickness of the spacer plate) so they do not prevent the shield from sitting flat on the spacer plate and chassis.

Connecteurs Arduino

Separate the 1×40-pin breakaway male header into the appropriate segments for connecting your Arduino and solder them to the shield. These header segments should be soldered to the sets of holes outlined with white rectangles on the top of the shield, with the pins facing up.

The A-Star 32U4 Primes and the newest Arduino boards, including the Uno R3 and the Leonardo, use one 1×10 header, two 1×8 headers, and one 1×6 header; older Arduino boards use two 1×8 headers and two 1×6 headers (the two pairs of pins highlighted above in red should not be populated if you are using this board with an older Arduino that does not support these additional pins). Please make sure you solder the appropriate headers for your particular Arduino!

An easy way to line up the Arduino headers for soldering is to plug them into an Arduino, then place the shield upside-down on top of them, as shown in the picture below. Be careful to insert the header pins into the correct set of holes before you begin soldering. Note: if you use this alignment technique, make sure your soldering iron temperature is not excessively hot and avoid holding the iron on a single pin for more than a few seconds as this could melt the Arduino’s female headers.

On the bottom of the board, trim the four Arduino header pins closest to the front of the board on each side to prevent them from contacting the motor housings. If you think there is a chance these pins might still touch the motor cases, you can put some electrical tape on the motors to act as insulation.

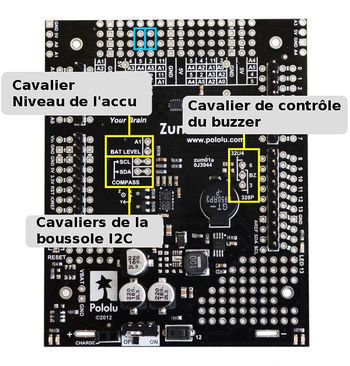

Cavaliers et connexions complémentaires

- Optional: If you want to enable the buzzer, enable the battery level input, or disable the compass, now is a good time to add and/or cut jumper connections to configure the shield to your liking. This can also be done later, though soldering to these pins is more difficult once the robot is assembled (especially if you decide later you want to add header pins for use with shorting blocks; this would require a lot of disassembly). The jumpers are explained in detail in Section 3.c. The buzzer and battery level jumpers can be connected by soldering in a short piece of wire between the two holes, while the compass I²C connections can be broken by cutting the trace on the top of the board between the holes.

Note: there is not enough clearance to use male headers on the battery level and compass I²C jumpers if you are using an Arduino with a DIP (through-hole) microcontroller.

| Instead of making a wire connection, you can solder a 1×3 male header to the buzzer jumper holes to allow the use of a shorting block for connecting the buzzer. You can also use male headers and shorting blocks for the battery level jumper and compass jumpers if you have an Arduino Uno with an SMD (surface mount) microcontroller, Arduino Leonardo, or A-Star 32U4 Prime. However, there is not enough clearance to use male headers on the battery level and compass I²C jumpers if you are using an Arduino with a DIP (through-hole) microcontroller. |

- Optional: At this point, you might consider soldering additional components (such as sensors), or headers or wires for connecting them, to the shield. If you do this, please check to make sure your part placement does not interfere with the shield’s ability to mate with the Arduino or the chassis. In particular, note that only components in the outermost three rows of the front expansion area can extend below the board (the fourth front-expansion row can only be used for pins extending above the board), and if you add any through-hole parts to the prototyping areas on the shield, you will need to drill corresponding holes in the acrylic spacer plate for the leads to fit into.

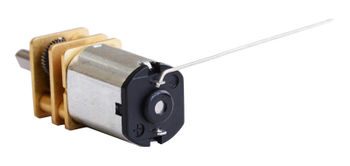

Les moteurs

- Cut two of the included jumper wires in half to form four segments, and trim off the ends that are covered in adhesive (the adhesive could interfere with making a good electrical connection to the motor). These wire segments will be used as motor leads.

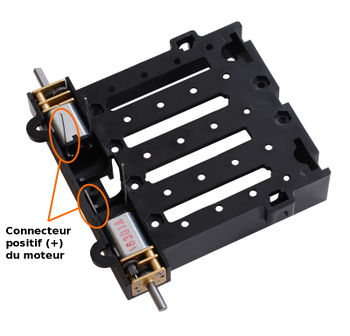

- Solder a pair of leads to each motor. You might find it helpful to make a small bend at the tip of each lead to hook into the hole in the motor lead tab to hold it in place for soldering. Warning: holding the soldering iron against the motor lead for more than a few seconds can start to damage the motor brushes, so try to be reasonably quick/efficient with this soldering; if the first attempt does not go well, remove the soldering iron and let the motor cool for a few seconds before trying again.

Each motor’s positive terminal is indicated by a plus sign (+) in the black plastic end of the motor, visible at the bottom of the picture above. The motors should be soldered into the shield with the positive terminal closest to the front, so you should attach the leads to allow the motors to be oriented this way. (However, don’t worry if you accidentally get the orientation of one or both motors wrong. You can later compensate for it in software with our ZumoMotors library.)

- Place the motors into the channel in the front of the chassis, aligning the gearbox with the grooves in the channel. The front plate of the gearbox should be even with the edge of the chassis.

Châssis et shield

| To assemble the chassis with the Zumo Shield, you should use the two-piece acrylic spacer plate that is included with the shield. You will not need the one-piece mounting plate that is included with the Zumo chassis. |

- Place an M3 nut in each of the two side slots near the rear of the chassis. The slots are sized so that nuts will not be able to rotate within them. (These nuts will be used to mount the idler sprockets later.)

- If you want, peel the protective paper masking off both sides of the acrylic spacer plate pieces (the spacer plates in our pictures show what they will look like with the masking peeled off). Alternatively, you can leave the masking on for additional thickness. If you leave the masking on, it will be mostly concealed when the robot is fully assembled.

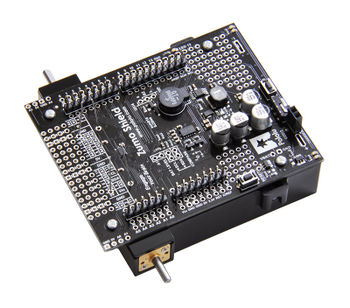

- Cover the chassis and motors with the spacer plate pieces and then the Zumo shield. The holes in the spacer plate should line up with the through-holes in the shield resting on top of it, and the motor leads should be aligned so they pass through the slots in the spacer as shown in the picture below. There is only one correct orientation for these plates. (The plate consists of two separate pieces to make it possible to disassemble the Zumo without having to desolder the motors or battery terminals.)

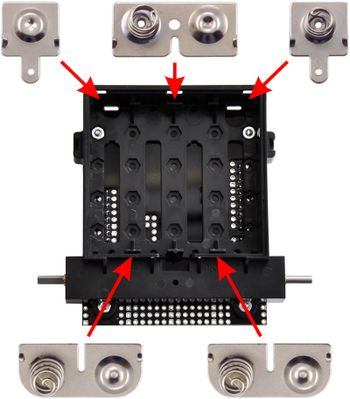

- In each of the four mounting holes, insert a #2-56 machine screw through the shield, spacer plate, and chassis, and tighten it against a nut under the chassis. It is usually easier to place the nut into the recess first and hold it there with a finger or piece of tape while inserting the screw. Note that the kit includes two different sizes of #2-56 machine screws: 1/4″and 5/16″. The two longer screws are intended for use in the front holes (near the motors) if you are also mounting a sumo blade; otherwise, you can use the shorter 1/4″ screws for all four mounting holes.

If you are also adding a basic sumo blade, you can either mount it now or add it later after you are done soldering the motors and battery contacts. (Note: If you intend to solder anything to the front expansion area of the shield, such as a Zumo reflectance sensor array, you will have more room to work if you do the soldering before adding the sumo blade.)

| There is a small chance the mounting tabs of the blade can cause shorts where it contacts the shield if the PCB solder mask is not thick enough, so we recommend adding some electrical tape or other insulating material between the blade and shield. |

To install the blade, first bend its mounting tabs to the appropriate angle. Next, place them on top of the shield so that the holes line up with the two front mounting holes and insert the two longer (5/16″) #2-56 machine screws (included with the shield) through the blade, shield, spacer plate, and chassis. Be careful when adjusting the angle of the sumo blade while it is mounted to the chassis, as this can crack the acrylic spacer plate if you apply sudden or excessive force. We recommend you do not try bending the blade while it is mounted to the chassis.

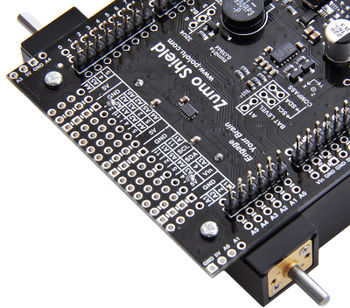

- Solder each motor lead to the shield, then trim off the excess length of wire.

Contacts des piles

- Turn the chassis over and install the battery terminal contacts as shown in the picture below. The three double-contact pieces should be firmly pressed into place until they are flush with the interior surface of the battery compartment. The two individual contacts should be inserted into the battery compartment so that their solder tabs protrude through the holes in the top of the chassis; you might want to temporarily tape these two individual contacts in place until they have been soldered to the shield as described in the next step, or you can use a battery to temporarily hold them in place.

Basé sur "Zumo Shield for Arduino" de Pololu (www.pololu.com/docs/0J57) - Traduit en Français par shop.mchobby.be CC-BY-SA pour la traduction

Toute copie doit contenir ce crédit, lien vers cette page et la section "crédit de traduction". Traduit avec l'autorisation expresse de Pololu (www.pololu.com)

Based on "Zumo Shield for Arduino" from Pololu (www.pololu.com/docs/0J57) - Translated to French by shop.mchobby.be CC-BY-SA for the translation

Copies must includes this credit, link to this page and the section "crédit de traduction" (translation credit). Translated with the Pololu's authorization (www.pololu.com)